Experiment done as a part for my Graduation Project at Design Science Lab

Mentors - Sweety TAUR, Sahil THAPPA

Technical advisor - Rohit MISTRY

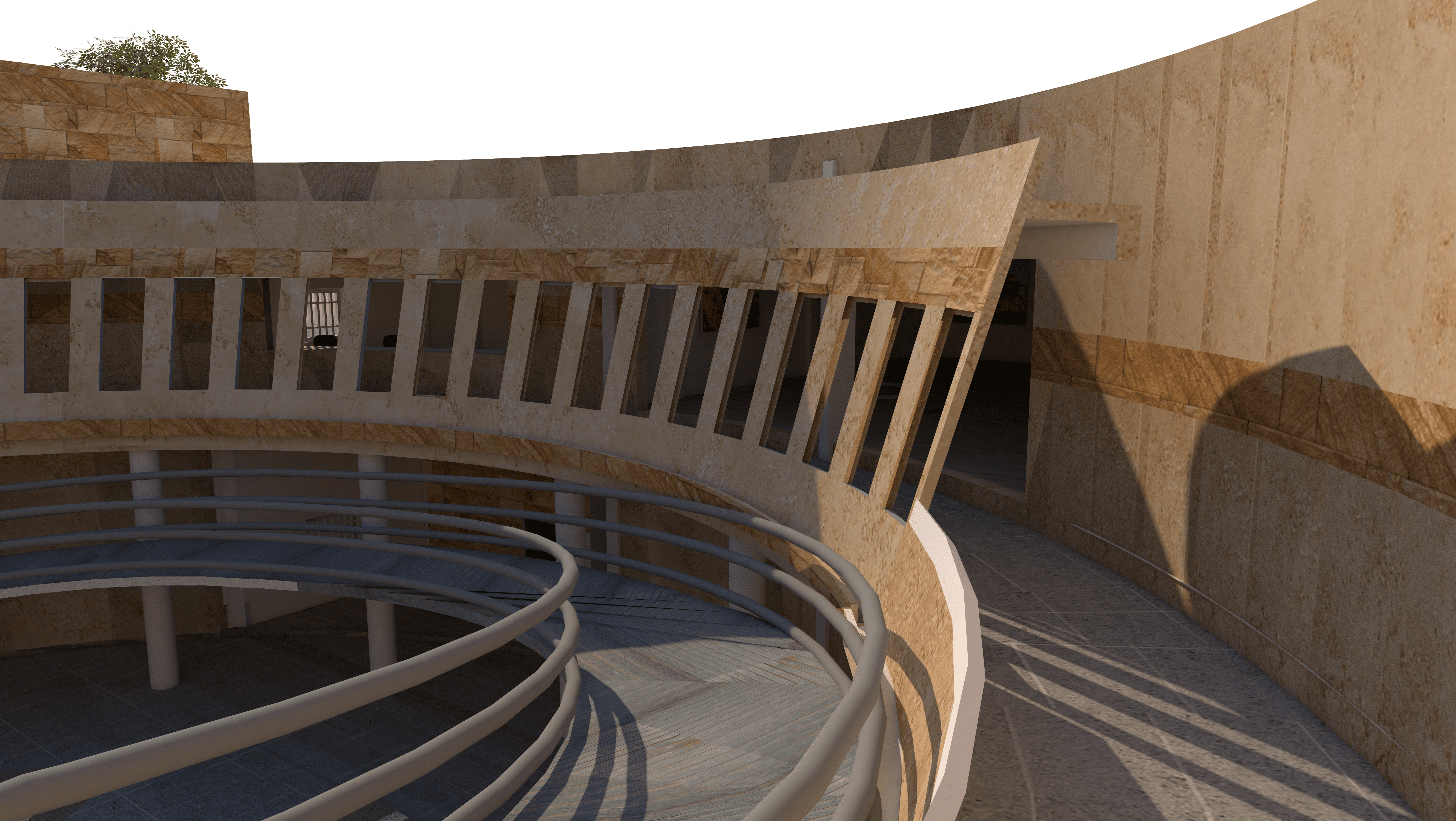

Taking an Einstein equation which connects Matter and Energy E = mc2 (square), and states matter can be connected into Energy and vice versa and defined as the fundamental concept of building blocks of Universe. All around us is matter, in everyday life Energy is required to change the state of motion of matter, it stores or transfers Energy depending on the various physical and chemical processes. the interplay between matter and Energy in Copper highlights their profounds interdependence. Electrical energy molds Copper & alloys in the given shape in an electric furnace, while copper wire transfers electric energy across distances. This duality showcases copper's role as both a material shaped by Energy and a conduit for Energy transmission, bridging the fundamental relationship between matter and Energy.

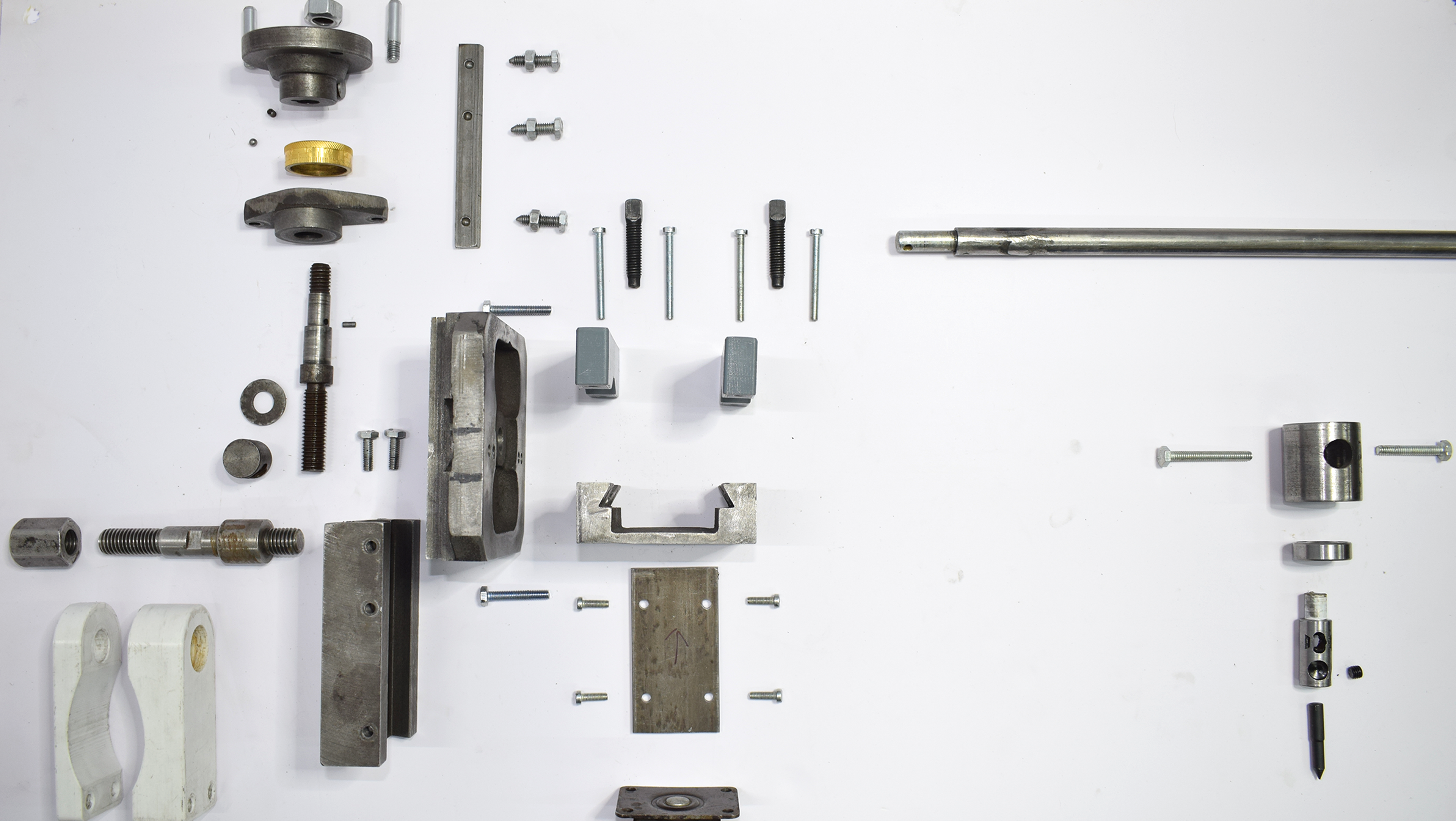

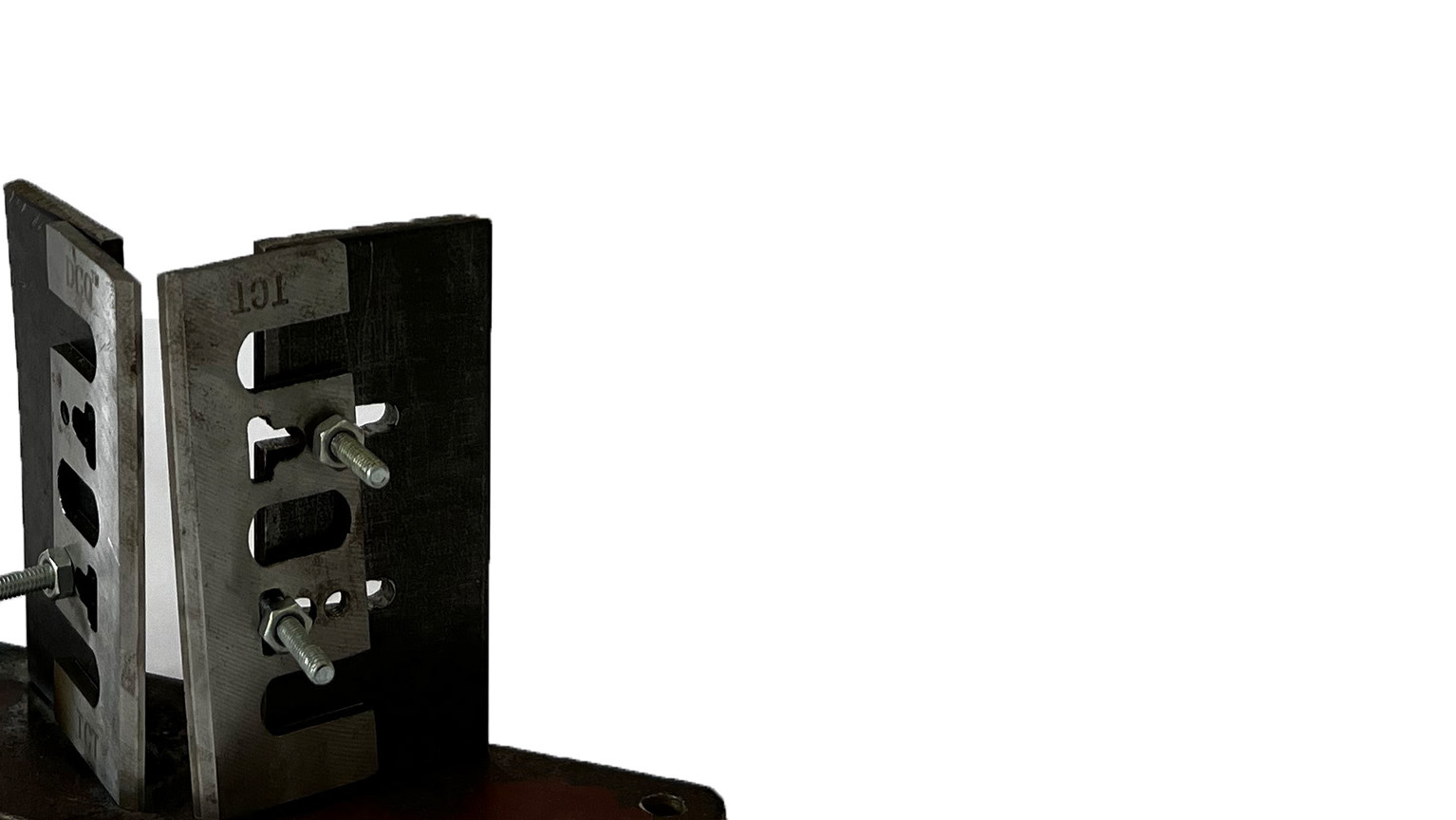

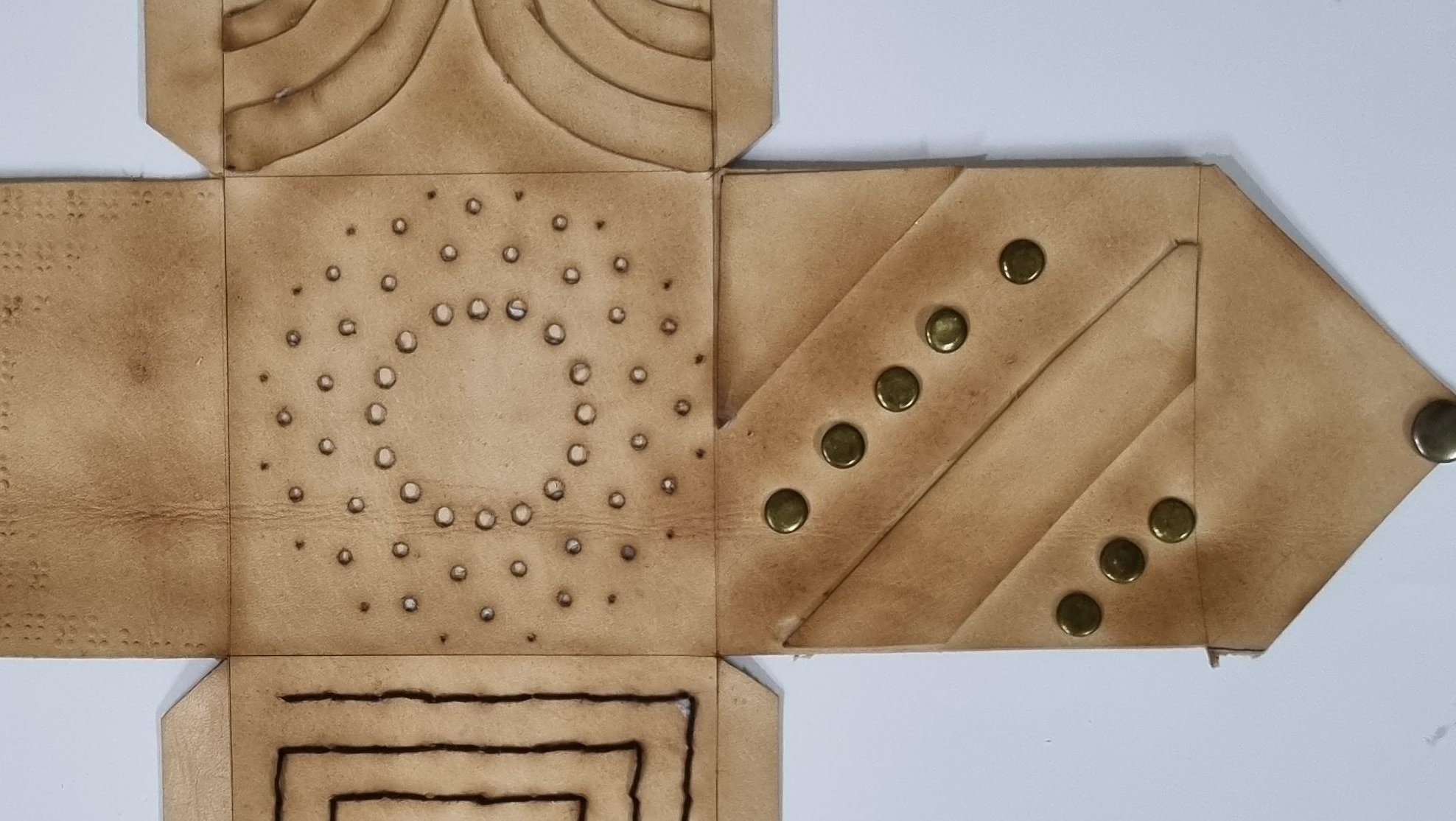

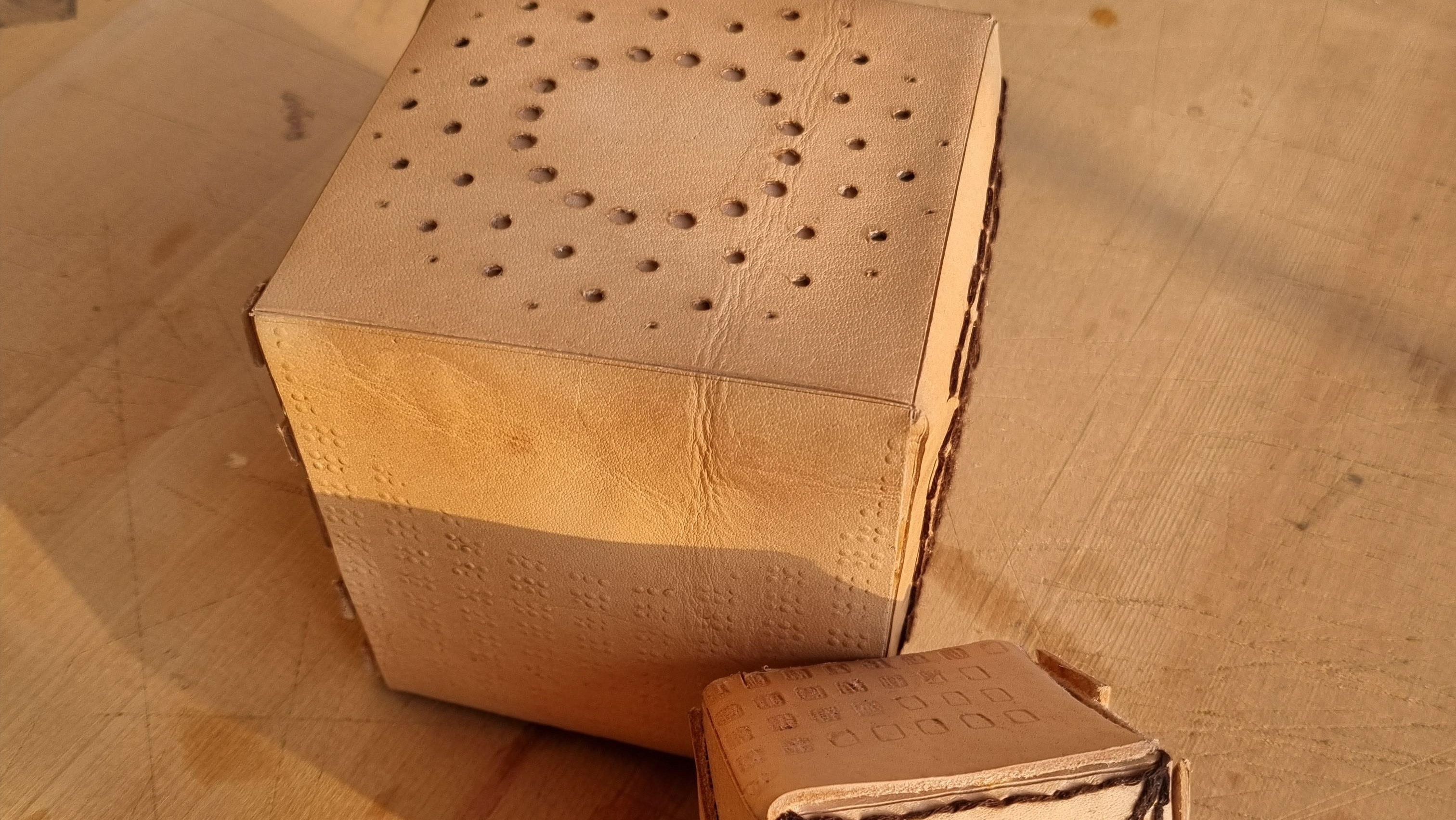

the making process

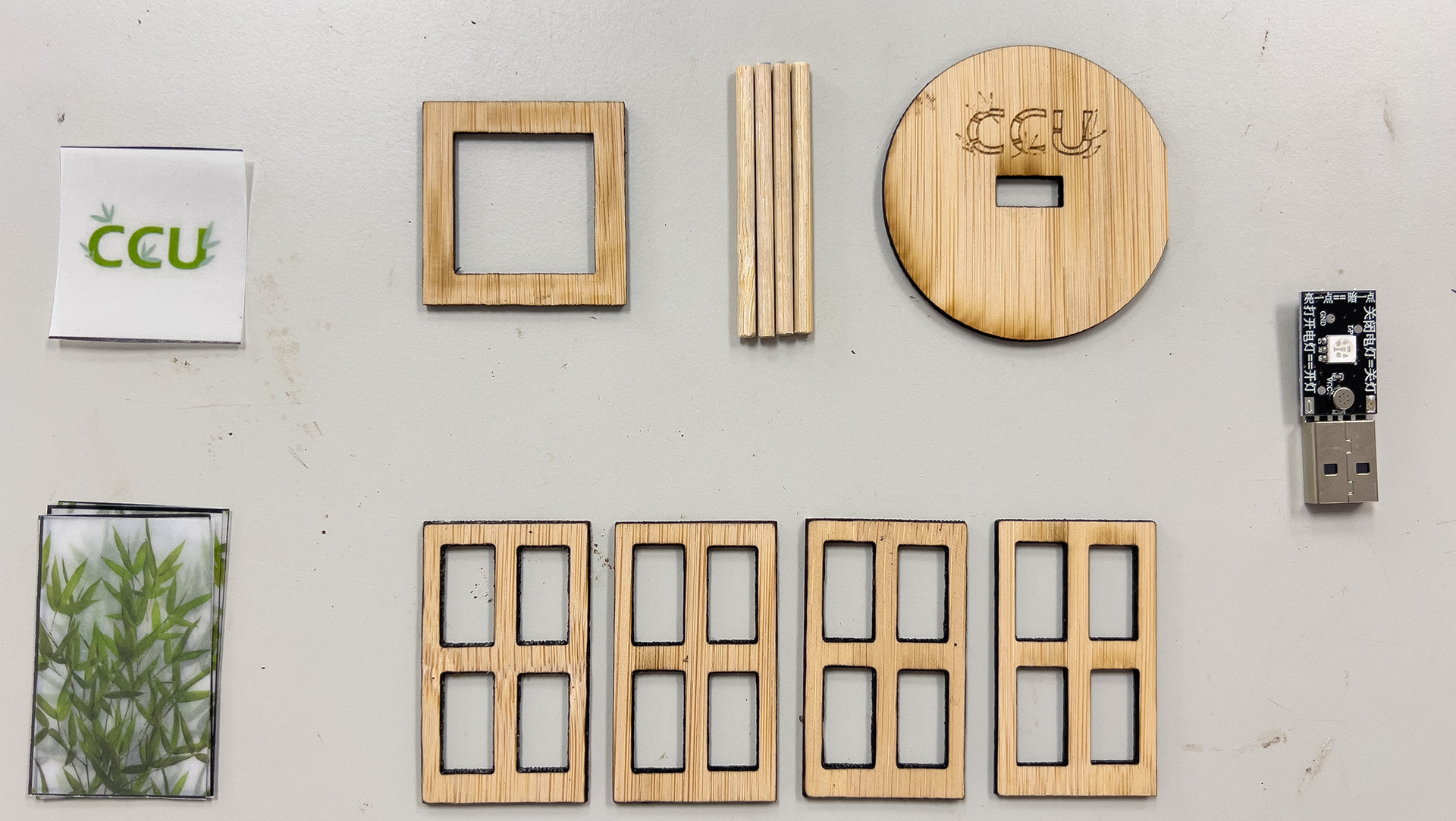

The experiment started as I was interested in lost-waxing , and as a designer . I wanted to create surface developments in metals by Art Deco. But to understand the material , the experiments were done with Copper and Copper Alloys. i intend to collect Raw material and cast the samples, but to create different alloys I collected some old Copper (Cu) tubes which were discarded from the AC Duct. Also Tin (Sn), Zinc (Zn), Nickel (Ni)

Terra Cotta mould dried for casting alloys

Melting copper in Electric Furnace

Casting Copper Alloys into Terra Cotta moulds

Casting of Aluminium Bronze

Terra cotta mould cracking after pouring the molten metal

While for casting my sample I used the electric Furnace for 1 hour, which means it cost ten rupees (10 cent).Questioning myself "How can it be so low cost?" Where does the energy in electric Furnaces comes from ?". The electricity comes from Power plant.

Energy used for casting is enormous accounting to use around 55% of the total Energy Cost. But still while I understand the system of the Electric Energy coming to furnaces is coming initially by burning fossil fuels, still the electricity is low-cost.

While the foreground systems in MSME's prioritize metal recycling, background system rely heavily on fossil fuels like coal or electricity generated from it. despite the shift from industrial age to information age elements of traditional metal casting still exist and put permanent pressure on natural resources, green house gas emissions, air and water pollution. economic growth also effecting the climate change and human health.