Graduation Project at Design Science Lab

Mentors - Sweety TAUR, Sahil THAPPA

Collabration with Camillo HUCK

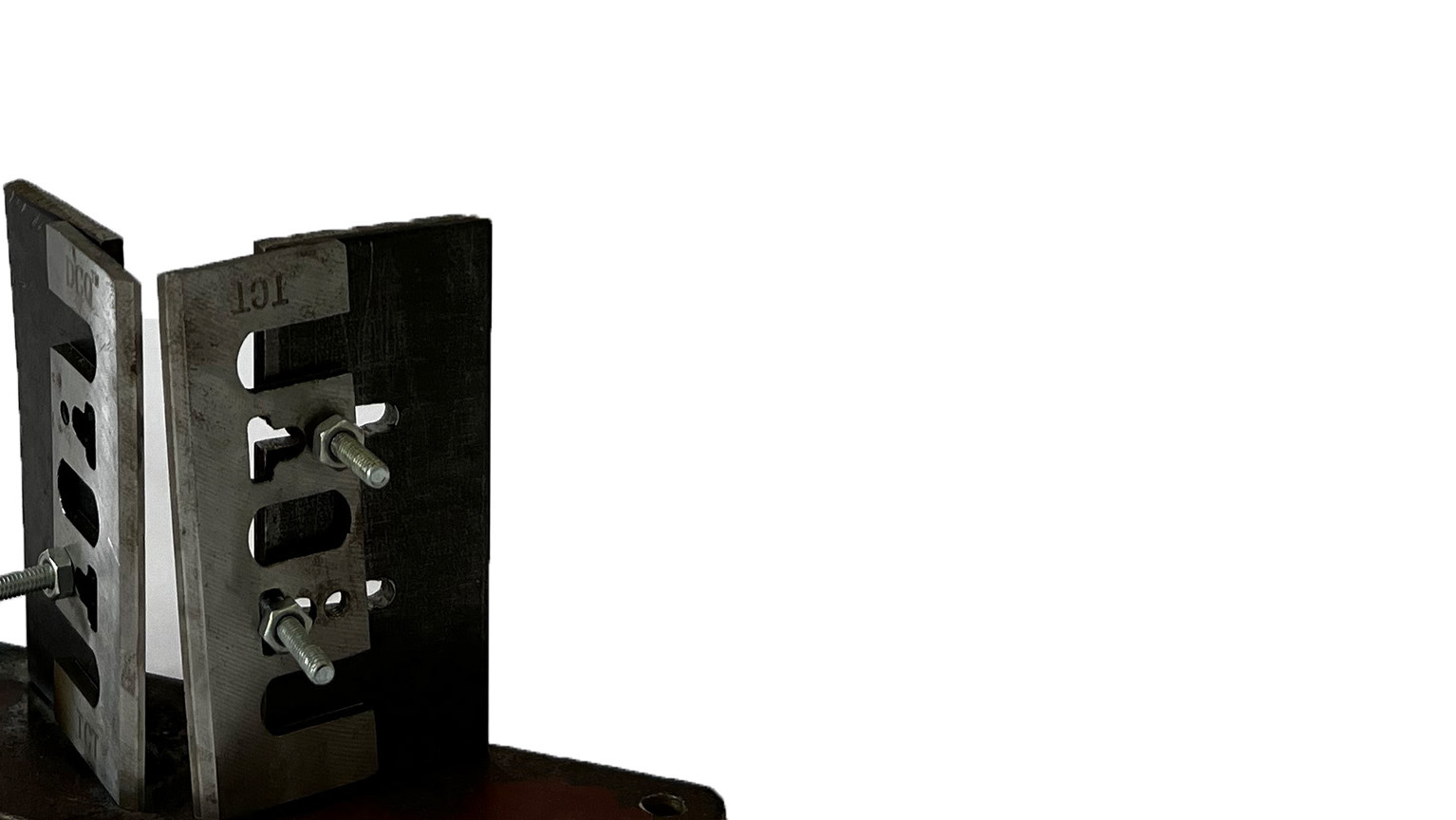

As for my earlier experiment the lens I created was on Lathe Machine. However, the process was limited by the maximum allowable lens size of 450 mm x 450 mm, and the temperature achieved during the operation reached approximately 300°C. Due to these constraints, producing a larger lens on a CNC machine proved to be unfeasible. Consequently, I developed the concept of a specialized tool that functions as a jig to accurately form the grooves of a Fresnel lens. This tool is capable of delivering high precision across all three axes, ensuring consistent and accurate groove formation for larger lenses. The tool was developed from an old piece of Lathe machine,which involved fully disassembling, renovating, and reassembling its components to suit the new application.

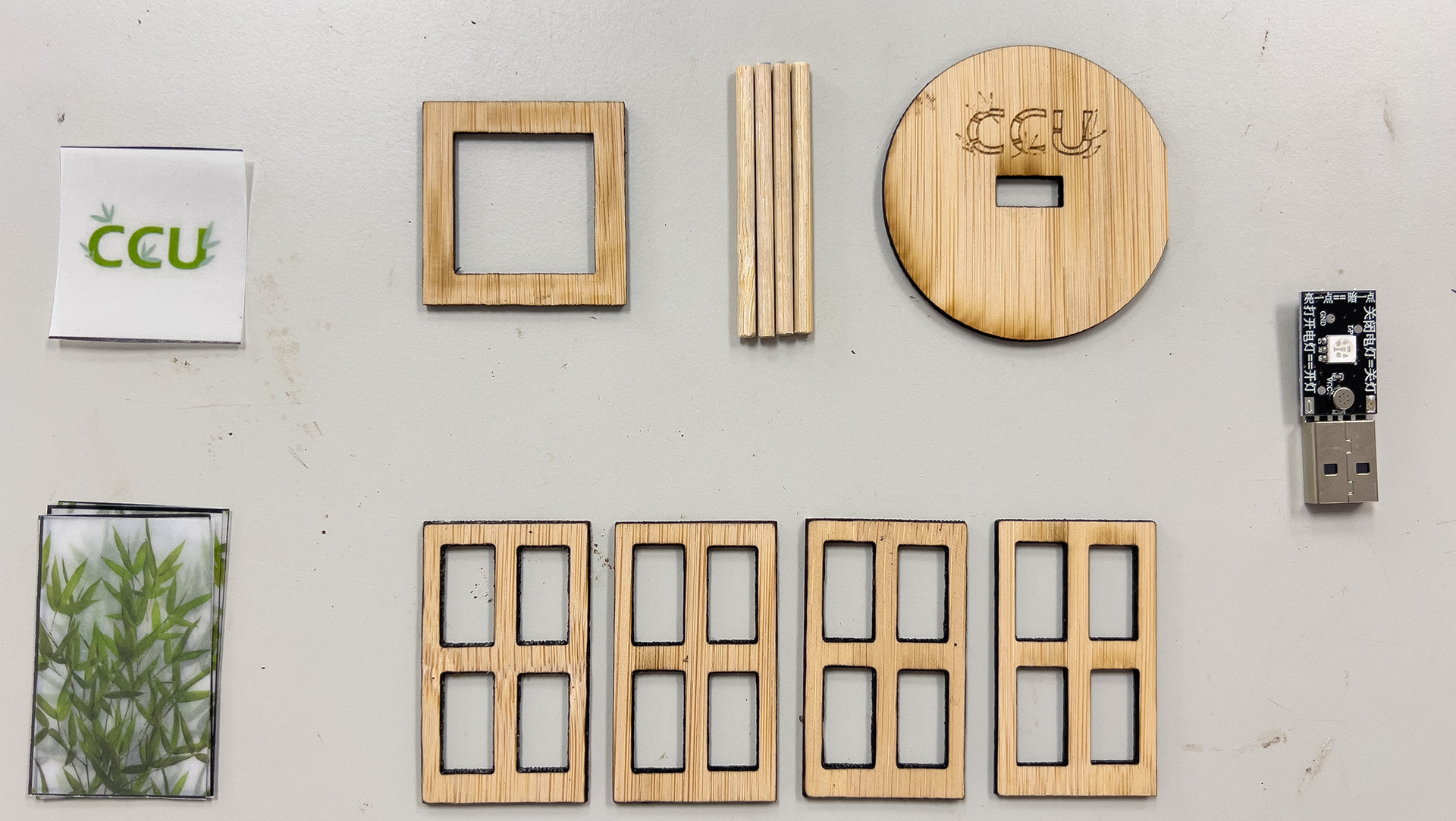

the making process

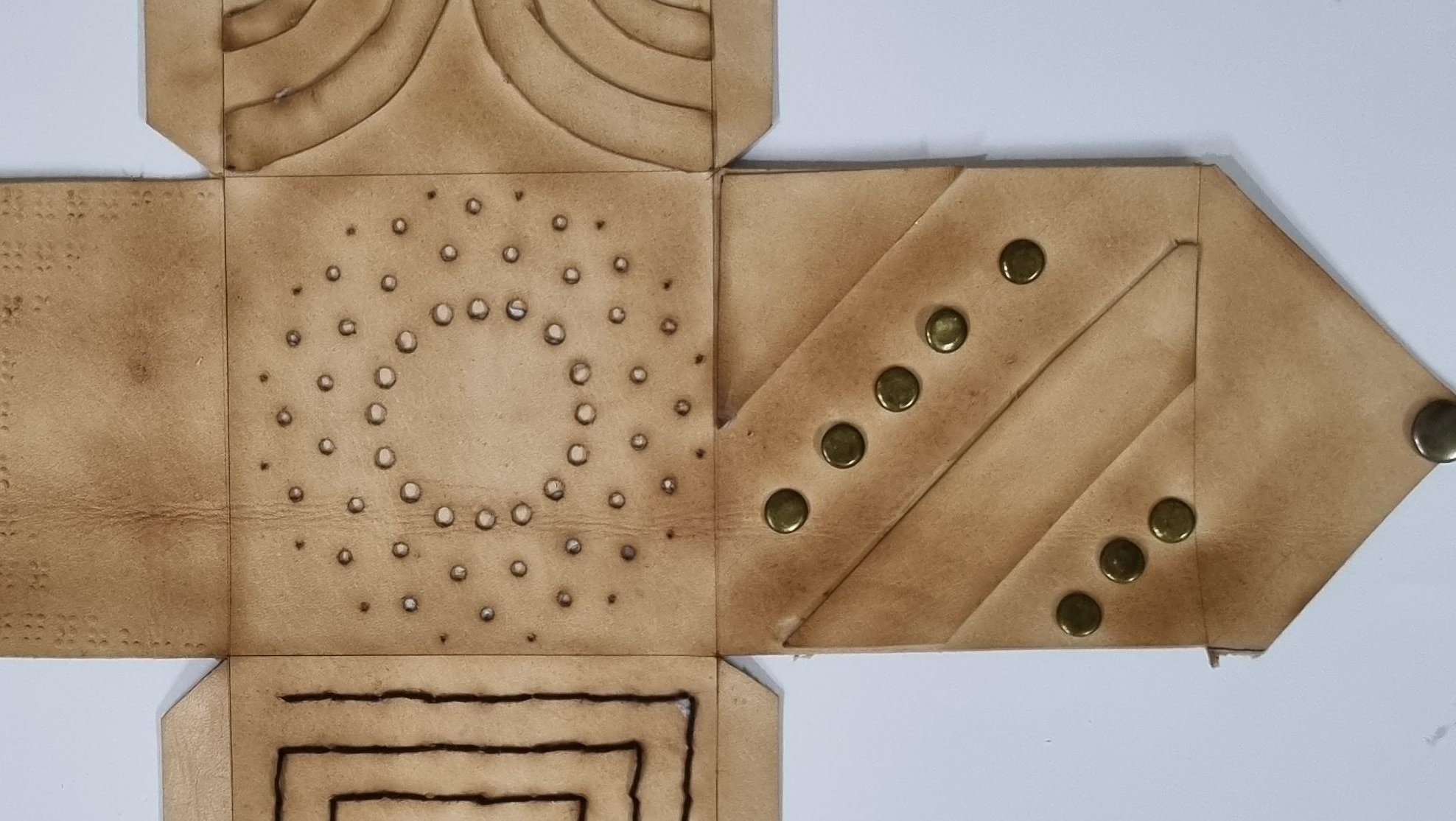

Prototype - 1

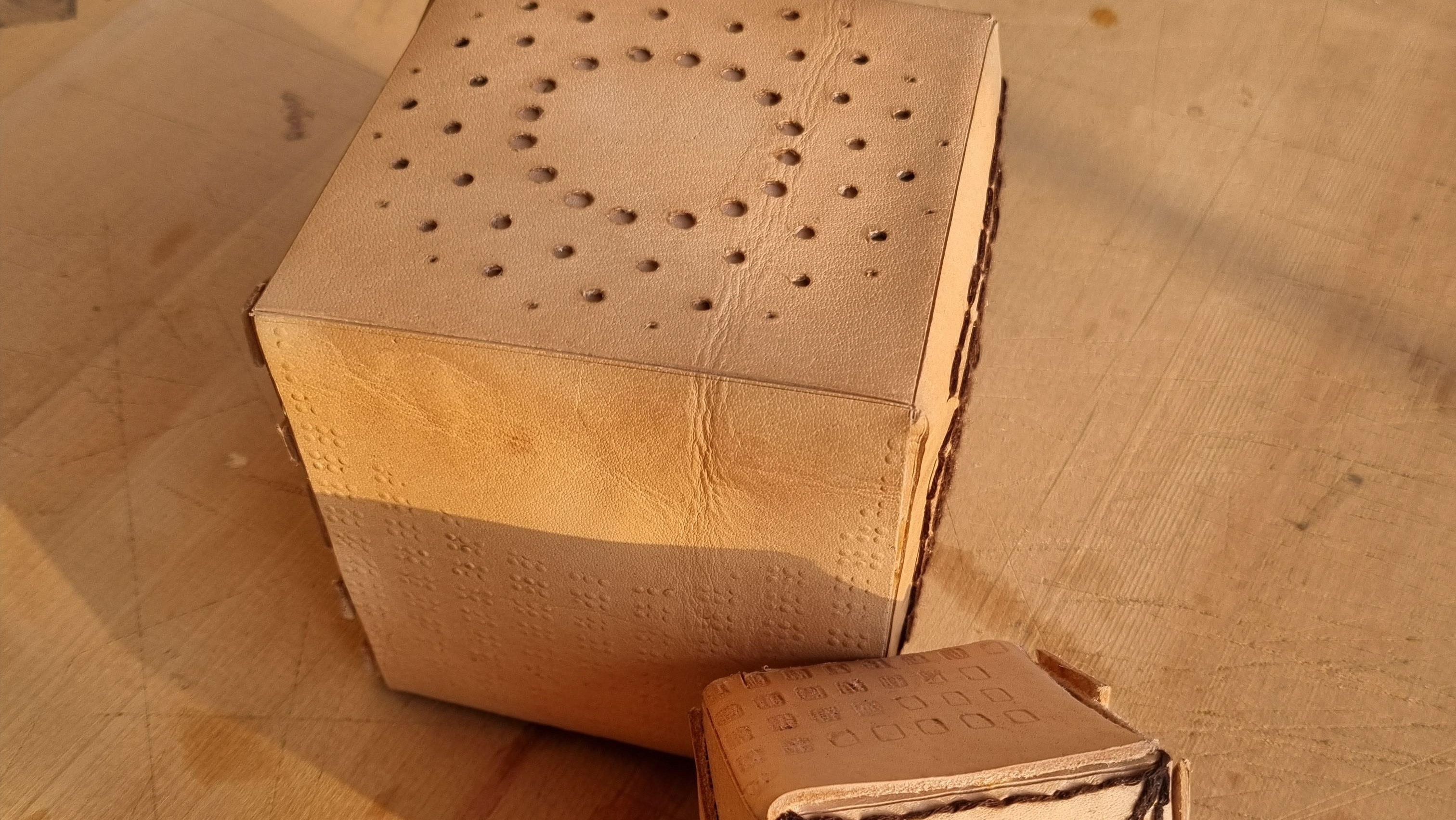

Prototype - 2